Production Process

Precision Manufacturing from Raw Material to Finished Product

-

1. Raw Material Preparation● Copper or aluminium conductors: Select copper or aluminium conductors suitable for high-voltage or low-voltage applications. Copper conductors are typically used for high-voltage cables.

-

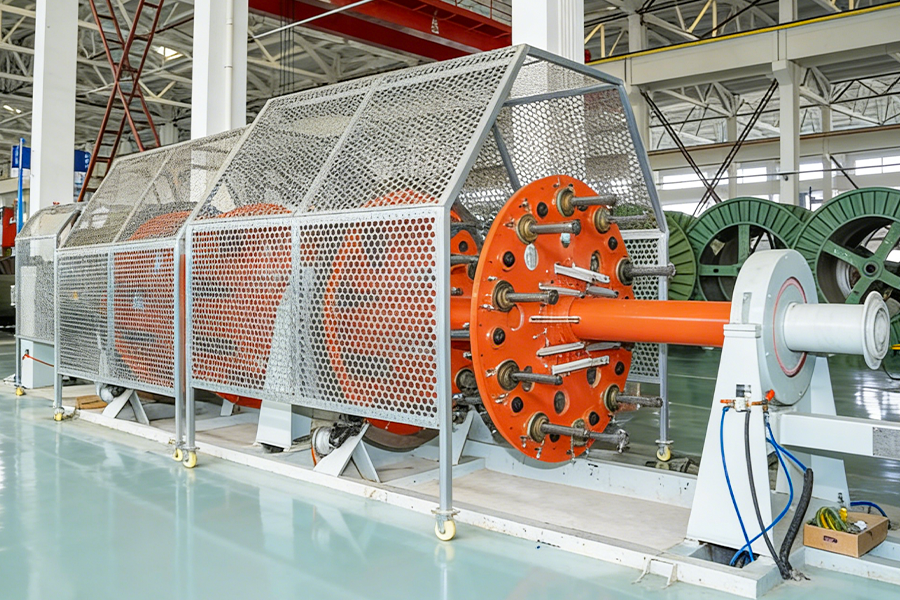

2. Conductor Processing● Wire Drawing: Copper or aluminium materials are drawn into wires of the required specifications.

● Stranding: Multiple fine wires are stranded together to increase mechanical strength and reduce resistance. -

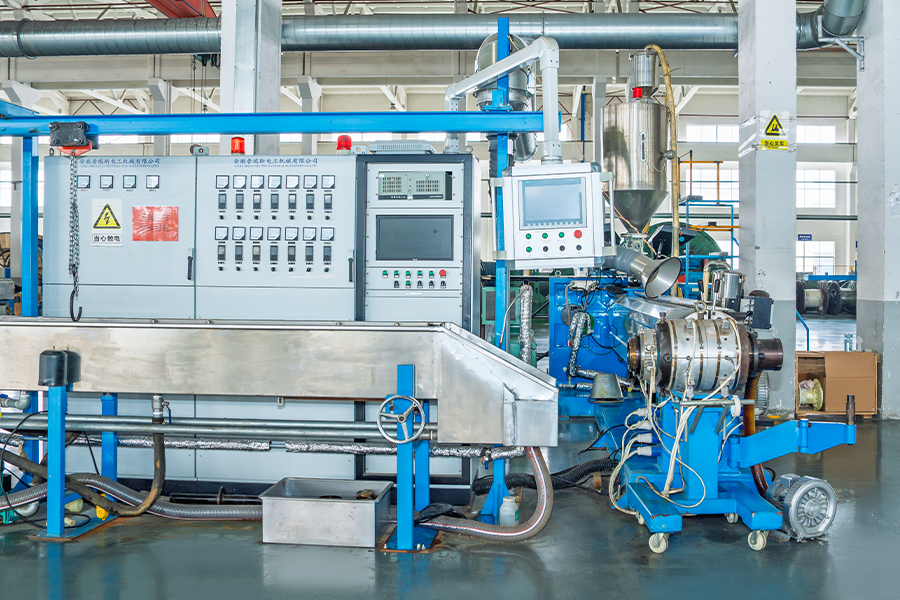

3. Insulation Layer Extrusion● Using an extruder to uniformly coat the conductor with insulation material to form an insulation layer.

-

4. Cable Formation● Conductor Stranding: Twisting multiple insulated conductors together to form the basic structure of the cable.

● Filling: Adding filler material to the cable to maintain its roundness and reduce air gaps. -

5. Sheath Extrusion● Sheath Layer: Extruding an additional layer of sheath material over the cabled structure to provide extra protection.

-

6. Armouring● Steel tape armouring: For high-voltage cables, steel tape armouring may be incorporated to enhance mechanical strength and resistance to electromagnetic interference.

● Steel wire armouring: Steel wire armouring is occasionally employed, particularly where additional tensile strength is required. -

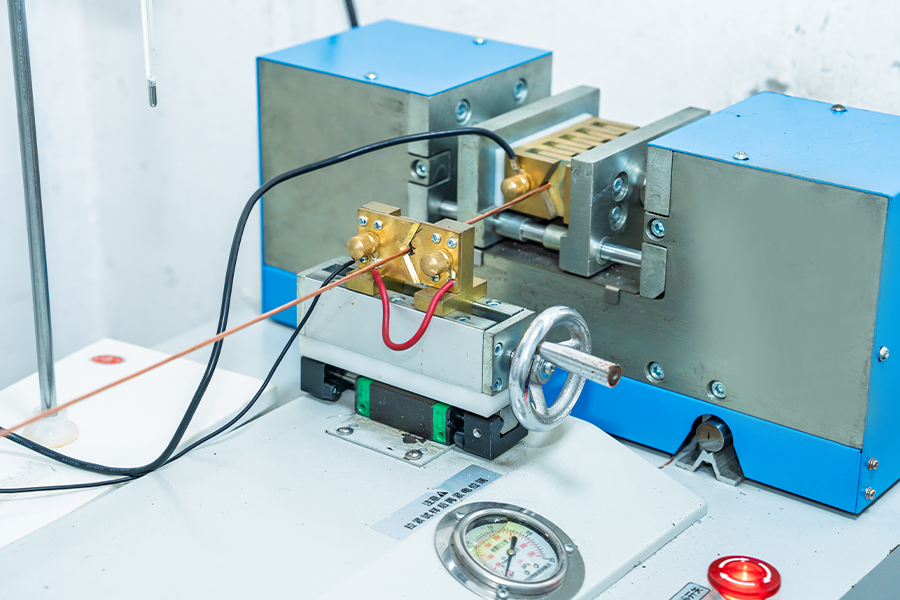

7. Testing● Conductor resistance test: Ensures the conductor's resistance meets specification requirements.

●Insulation Testing: Inspect the integrity and electrical performance of the insulation layer.

●Sheath Testing: Verify that the physical and electrical properties of the sheath material meet the required standards.

Quality Manufacturing

Our cable products undergo rigorous performance testing and safety certification, and are widely used in the fields of power transmission, industrial automation, and urban construction. We believe that through continuous technological innovation and process improvement, we can continuously enhance product quality to meet the needs of customers worldwide.

Production Advantages

Advanced Equipment

By operating our own factory and managing the entire supply chain, we eliminate intermediaries. This direct control enables stringent quality assurance at every step and ensures reliable, short lead times.

Language

Language

English

English عربى

عربى