Power Cables Solution in China

About Us

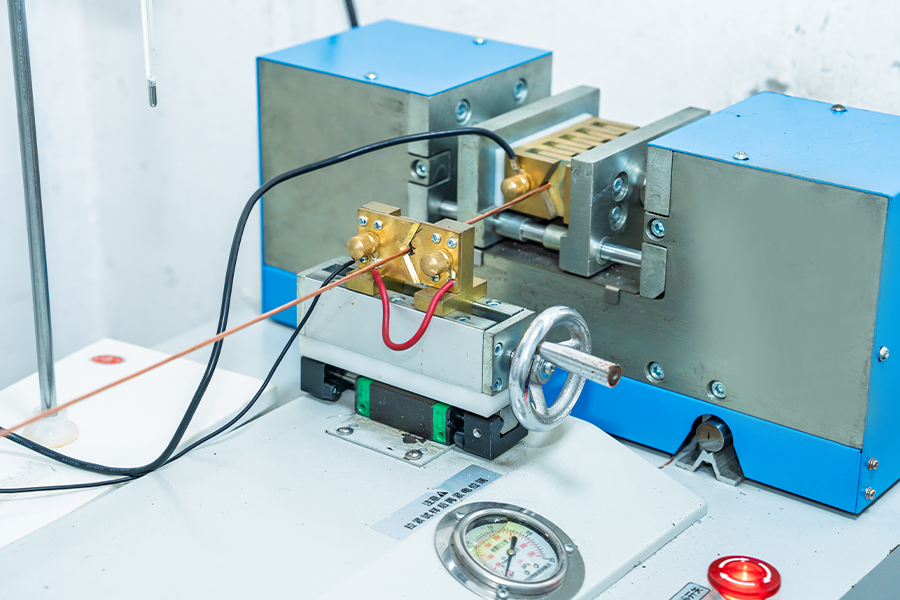

Factory Tour

Contact us now

Latest Enterprise and Industry News

-

2026-03-02

2026-03-02 Industry News

Industry News -

2026-02-24

2026-02-24 Industry News

Industry News -

2026-02-18

2026-02-18 Industry News

Industry News

industry knowledge

The Importance of Cross-Linked Polyethylene (XLPE) in Power Cables

Cross-linked polyethylene (XLPE) is a key material used in the construction of power cables, offering significant improvements over traditional materials like PVC. The process of cross-linking the polyethylene molecules enhances its physical properties, such as thermal resistance, mechanical strength, and insulation capabilities. This makes XLPE cables a more reliable choice for various high-demand applications. At SANXIN, we pride ourselves on producing top-quality XLPE cables that provide long-lasting durability and superior performance, making us your trusted partner for power cable solutions.

Advantages of XLPE Cables Over Conventional Cables

XLPE power cables offer several advantages over traditional cables. These benefits include:

- Higher thermal stability: XLPE can withstand temperatures up to 90°C continuously and up to 250°C for short periods, making it suitable for high-temperature environments.

- Superior electrical properties: XLPE has lower dielectric losses, which helps improve the efficiency of the electrical transmission and reduces energy losses.

- Enhanced mechanical strength: The cross-linking process provides added resistance to impact, pressure, and physical damage, reducing the chances of cable failure.

- Excellent chemical resistance: XLPE cables are more resistant to water, oils, acids, and other chemicals, which increases their longevity and performance in harsh environments.

Our self-manufactured XLPE cables come with added peace of mind, ensuring your projects are built to last with minimal downtime.

Applications of XLPE Cables in Power Transmission

XLPE cables are widely used in various industries due to their superior properties. Here are some of the most common applications:

- Power transmission and distribution systems: XLPE cables are essential in both underground and overhead lines for safe and efficient power distribution.

- Renewable energy installations: These cables are perfect for use in solar and wind energy systems where reliable, durable, and high-performance cables are necessary to withstand harsh conditions.

- Industrial applications: XLPE cables are also commonly found in manufacturing plants, factories, and processing units, where they are exposed to heavy machinery and high-voltage power needs.

Key Considerations in Choosing XLPE Cables

When selecting XLPE cables for your projects, several factors need to be considered to ensure maximum efficiency and safety. These include:

- Voltage rating: The cable should be able to handle the voltage requirements of your application. SANXIN’s range includes XLPE cables suitable for low, medium, and high-voltage systems.

- Temperature range: Consider the temperature conditions in which the cable will operate. XLPE’s high thermal resistance allows it to perform well in extreme temperatures.

- Mechanical protection: Ensure the cable has adequate protection against external factors like pressure, abrasion, and rodent damage, especially in industrial and outdoor settings.

Our commitment to quality ensures that all of our XLPE cables meet rigorous industry standards, providing a reliable solution for even the most demanding environments.

Manufacturing Process: From Raw Materials to Finished Products

At SANXIN, we take pride in overseeing every step of our cable production, ensuring that each cable meets our high standards. Our integrated manufacturing process includes sourcing the finest raw materials, precisely controlling the production conditions, and conducting rigorous testing on each finished product. This comprehensive approach guarantees quality and short delivery times, as we manage the entire process in-house.

Benefits of In-House Production

By managing everything from raw material selection to production and sales, we ensure that:

- We can maintain strict quality control at every stage.

- Production times are kept short, so you receive your products faster.

- We can offer competitive pricing by cutting out middlemen and managing costs efficiently.

With over 10,000 product specifications, our customers can find the perfect solution for their specific needs, backed by our commitment to quality and reliability.

Why Choose SANXIN for Your Power Cable Needs?

When you choose SANXIN for your power cable requirements, you are opting for a company with years of expertise, quality control, and a passion for innovation. Whether you need Cross-Linked Polyethylene XLPE Cables or other specialized solutions, we are here to support you with high-performance products that help you power your projects with confidence.

Language

Language

English

English عربى

عربى